Office Address:4th floor, Chuangrong Building Block C, Danshan Road, AnzhenStreet, Xishan District, Wuxi, Jiangsu, China.

Factory Address:No.26 Jingrui Rd, Xibei Town, Xishan District, Wuxi, Jiangsu, China.

Skype: tnjd168

Email:info@powermaxgasifiers.com

Email:sales@powermaxgasifiers.com

Mobile/WhatsApp: +86-13812083566

Tel:+86-510-68229610

Project | Technical specification | ||||||||

Generator | Model of the set | 400 GFLS | 500 GFLS | 800 GFLS | 1000 GFLS | ||||

Rated Power(KW) | 400 | 500 | 800 | 1000 | |||||

Rated Voltage(KV) | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | 0.4 | 0.44 | |

Rated Current(A) | 721 | 656 | 902 | 820 | 1443 | 1312 | 1804 | 1640 | |

Rated Frequency(HZ) | 50 | 60 | 50 | 60 | 50 | 60 | 50 | 60 | |

COS Φ Power Factor | Lagging | ||||||||

Mode of Excitation | Brushless | ||||||||

Phase & Connection | 3 Phases 4 Wires | ||||||||

Generator Model | 1FC6 SIEMENS | ||||||||

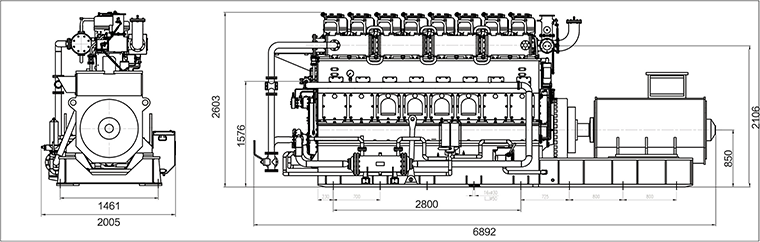

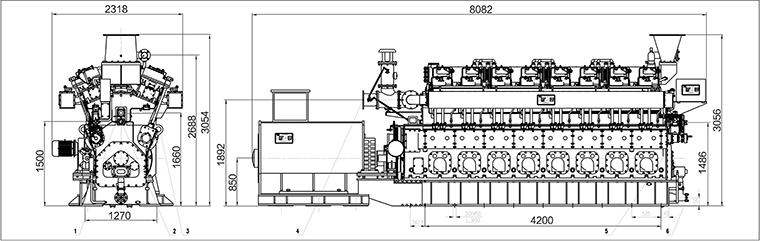

Overall Dimensions(mm) | 6500*1830*3100 | 8287*2421*2782 | |||||||

Net Weight(kg) | 22000 | 40000 | |||||||

Engine | Model of Engine | TNJD-8300Q1 | TNJD-8300Q2 | TNJD-16V300Q1 | TNJD-16V300Q2 | ||||

Mode | Water-cooling,Four-stroke,Spark plug ignition,Open combustion chamber | ||||||||

Natural aspirated | |||||||||

Arrangement of Cylinder | In-line 8-cylinder | V model 16 cylinders | |||||||

Cyclinder Diameter(mm) | 300 | ||||||||

Stroke(mm) | 380 | ||||||||

Rated Power(KW) | 440 | 550 | 880 | 1100 | |||||

Speeding(r/min) | 500 | 600 | 500 | 600 | |||||

Direction of Rotation (Dependent on Flywheel Start-up Mode) | Counterclockwise | ||||||||

start-up Mode | Compressed Air | ||||||||

Exhaust Temperature of Cylinder(℃) | ≤580 | ||||||||

Temperature of Gas Tunrel Boring Machines(℃) | ≤40 | ||||||||

Gas Pressure(Kpa) | ≥2.5 | ||||||||

Oil Consumption(g/kwh) | ≥1.0 | ||||||||